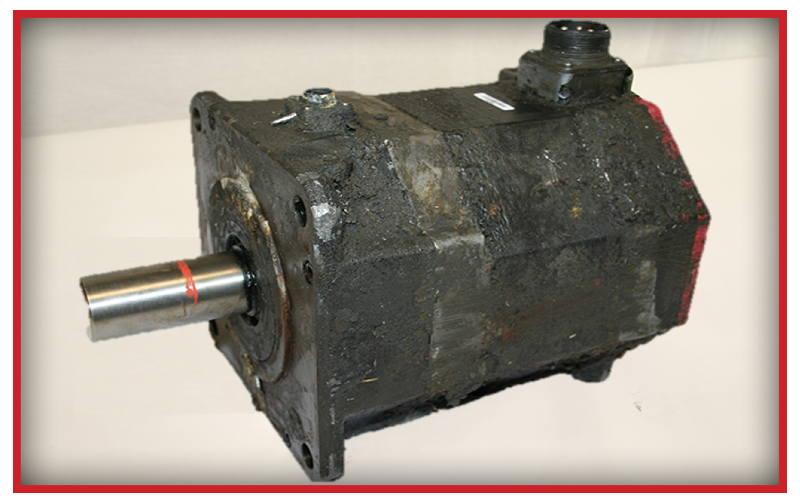

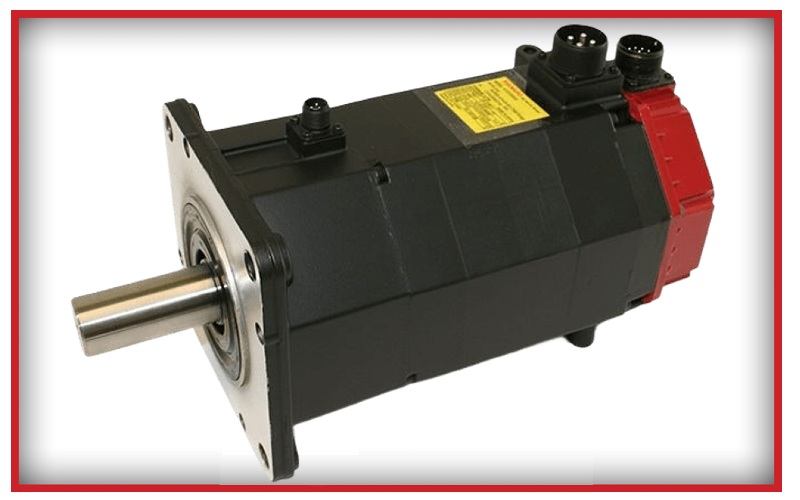

McBROOM SPECIALIZES IN AC AND DC SERVO MOTOR REPAIR

McBroom has a commitment to provide our customers with the highest quality service. Our services include state-of-the-art OEM tests to provide quick, accurate diagnostics to the component level, allowing us to repair servo motors that meet or exceed manufacturer specifications.

Our complete in-house repair capabilities include machining, balancing, rewinding and re-magnetizing. These in-house repair advantages allow us to have complete control of turn-around time on all repairs.

– Meg and HiPot Windings

– Mechanically run unit opposite rotation and record output signal of control device

Utilizing Mitchell testing equipment (designed to conform proper calibration of encoder or resolver output signal), ensure output signal is correct and meets manufacturer’s specifications.

Physically connect motor to drive system in test cell and run unit to simulate same duty cycle as seen on shop floor. Run unit and generate vibration spectrum.

– Increased machine uptime

– Greatly reduced turnaround time

– Design enhancements increase your repair cost savings

BRANDS SERVICED INCLUDE:

ABB

AEG

ALLEN BRADLEY

AMETEK

AMK

BAUMUELLER

BAUTZ

BBC

BERGER LAHR

BODINE

CINCINNATI MILICRON

CMC

CONTRAVES

CUSTOM SERVO MOTOR

DENSO

ELMO

EXLAR

FANUC

GE FANUC

GEORGII KOBOLD

GETTYS

GIDDINGS & LEWIS

GOULD

GROSCHOPP

INDRAMAT

INDUSTRIAL DRIVE

KOLLMORGAN

KUKA

LENZE

MAGNETEK

MOOG

MTS

OMRON

PACIFIC SCIENTIFIC

PANASONIC

PARKER

PEERLESS WINSMITH

PERSKE

POWERTECH

RELIANCE/ELECTROCRAFT

SEM

SIEMENS

SIGMA

SUMITOMO

SEW

TOSHIBA

UNICO

VICKERS

WHEDCO

YASKAWA